Our Approach

iSQUARE has a dedicated team of Business Analyst, UI/UX Designer, Project Manager, Technical Architect, Front-End Developer, Back-End Developer, Tester and DevOps to work on this GMS project. In response to the client's clear instructions, our team established an effective communication workflow that aided us to prevent misunderstandings and confusion between us.

After many detailed meetings with our clients to discuss their goals with the system, we finalized our requirements for the end product and moved further to the planning and implementation stage.

Our business analyst analyzed the business, gathered the requirements and shared it with the client for their approval. Once approved, the UI/UX designer completes the design of the screen and once again shared it with the customer. In the meantime, the technical architect prepared the project setup and built the architecture.

After that, the developers developed the code and passed it to testers who tested the code, and the dev-ops team deployed it to the server. After the successful implementation of the project, the project team handed over the project to the support team. And the support team took care of all subjects and clarifications through SLA.

Final Result

We successfully implemented a Garment Manufacturing Software within a year of project duration with all the specifications needed by the client. The new platform comes with a better user experience, scalability, data maintenance and easier usability.

The final product is a cloud-based system that helps the client in effective data gathering. It contains the data for the last 5 years and they can be viewed by sorting and filtering the data. We have also installed a bar code system that can be used in every stock.

The main advantage of this system is it can open multiple tabs inside the system. The private system can be only accessed by the members and is password protected. The authorisation control has been given to the super admin who has control of the entire system.

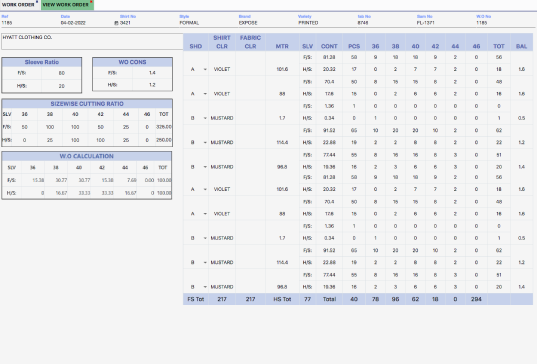

The GMS consists of several departments such as purchase, textile, R&D, work order, factory, sales, and warehouse. Each department data will be handled by the responsible person in the department and the manager can view all the data in a single place.

One of the key features of the system is they can view the livestock report. The stock types are divided into SHIRT STOCK, ESTIMATE STOCK, BEF.AC CUTTING STOCK, AFT.AC CUTTING STOCK, TEXTILE STOCK, LR STOCK, DAMAGED STOCK, and BUNDLE STOCK. The overall stock report can be viewed under these types.

We also included a section called Seasonal Master where they can view the data about the sales report, purchase report and production report for the selected seasons. For example, they can only filter the details of sales for the Christmas season for a particular year. Also, we made an option to do year comparison and seasonal comparison to have a better understanding of their business performance with the last 5 years sales comparison data to improve sales.

The client needed to add the pricing of every piece of shirt manufactured with the help of the R&D team. The pricing of every piece will be calculated automatically by the system with the price range of the raw materials used, production cost and the extra add-ons used in the finished piece.

Client Impact

With the final product, the client can see a major scaling in their business. They have transformed into a 5x system driven company with an increase in their production and revenue after implementing the GMS. The efficiency of the team has been improved with the detailed reporting available within the system. Both our client and the iSQUARE team are pleased with the final output of the Garment Manufacturing Software.

Do you want to scale your business performance and revenue with the help of a customized software solution like this? Dedicate this task to iSQUARE and relax.